Transformation

This is the second in an occasional series of notes in which I try to document life at the frontier of existence as an old age pensioner.

Well, the metamorphosis is complete. I started retirement in 2008 as a shirker by brain and have emerged a year later as a fully fledged worker by hand. Here are the badges of my new status; a pair of rigger's boots, safety glasses and a bright yellow hard hat. If you don't think that a hard hat is an absolutely necessary retirement accessory, try working in the loft of a house for a week replacing the skimpy carcinogenic insulation with the latest recycled glass bottle material. At the ridge, there is over three metres of headroom, but it is easy to forget that this drops away to nothing at the edges.

Apart from a few lumps on the head my health and fitness level continues to improve. In 2007, at sixty three, I had the body of an eighty year old; two years later, having lost 30 kilos in weight and dropped my blood pressure from 165 over 103 to 129 over 77, I have the body of a forty year old, with my chest once more bigger than my waist.

Like Benjamin Button I am aging backwards and look forward to experiencing my teens with a brain this time.

End of an epoch

I guess the biggest news is that mother-in-law has finally laid her hammer down at the great age of 96. Back in the summer, she had a fall and broke her hip; not in itself fatal, but once she was in hospital everything went wrong, including catching MRSA. We managed to get her back to her home for the last few days and she finally gave up the ghost in that low point of the night around 3 am.

A funny old South African doctor came to check that she was dead. After the usual light on the eyeballs, feeling for a pulse and checking for breath, he spent some time arranging her mouth in a smile before rigor mortis set in. Apparently in S.A. they tie a cloth under the chin and over the top of the head to stop the mouth lolling open.

You feel so useless at a time like that don't you. After turning off the oxygen concentrator and unplugging the bed, it was just waiting for the next step in the final act of the dance of life and death. I thought that she would be satisfied with how she looked in death: Hair neatly permed, skin far too smooth for a person of her years; the sleek polished appearance that had been her armour for much of her life seemed to have returned in death.

She lived by her wits and good looks; first crossed the Atlantic on the Queen Mary in the nineteen thirties, married a French engineer and spent summers in the sixties touring Europe in a VW microbus. We found three passports amongst her possessions; one English, one American and one French. I did not like many of her ideas or sentiments, but I did have a sneaking admiration for her. Still do.

Tooled up

I have to admit to being a bit of a tool nut and, having bought a fair number of tools on the net, I get a goodly selection of tool catalogues dropping through the letter box and spend many a happy hour relaxing with a mug of coffee and the latest array of drills, presses, thingies for removing stuff and thingies for putting stuff on.

However, not all catalogues are equal and the one I anticipate most eagerly is the one sent out by the Northern Tool & Equipment company. The winter 2009 edition arrived the other day and within its pages I find such gems as a 4000 psi pressure washer, which would not only wash the surface off the patio, but would probably blow the patio into next door's garden. Still, once we have lost the patio, we could always hire the pressure washer out to the local police for crowd control.

Or what about a biodiesel starter kit. For around £1500 you could make up to 40 litres of biodiesel a day, using waste vegetable oil from the local chippie. Of course you will need the wall mounted dispensing pump to get your 15 pence a litre biodiesel from the processor to your car. This comes with a 4 metre delivery hose, auto shut off nozzle and flow meter with an accuracy of +/- 2%. After all you cannot be too thin or too accurate when pumping biodiesel.

The radio fence pet containment system at £86.24 takes approximately fourteen days of training, so for the first thirteen days you will still have to run after your pet and drag it back; or maybe that's fourteen days to train you to ignore the neighbour's howls of protest when Fido rampages through his rose beds and shreds the kids paddling pool.

£1034.99 may seem a little steep for a hand brake and as this one weighs in at 380kg you may need to upgrade your shock absorbers. A hand brake, as all of you will know, is a metal bending machine and there is a picture of someone operating it. What is odd is that there doesn't seem to be any metal in the machine: I have looked in vain for the invisibility cloak accessory.

Sausage stuffers come in both vertical and horizontal configurations, but I am not sure which is best. The vertical stuffer apparently "produces great tasting sausages", but the exact effect that gravity has on the taste of sausages is not explained. The horizontal stuffer on the other hand gives a "professional appearance". Not to the sausages you understand. No, the stainless steel cylinder and feet give the horizontal stuffer a professional look that is clearly of considerable importance.

Anyway, the coffee is getting cold, so I have to make a decision. If I get the pressure washer, with the sludge suction pump accessory, perhaps I could clean out the pond. On the other hand, with 4000psi I may suck the pond right out of the ground, so maybe I should just stick to the inflatable air bag that goes under a vehicle accelerator pedal to "reduce extreme acceleration peaks" and improve fuel consumption. With that I could get the 18 piece set of lock picks, just in case I get locked out of the car. This comes with a notice telling you that it is not intended for illegal uses, so that's ok. Decisions, Decisions; I need another coffee.

Garden of delights

The second season of my drive to self-sufficiency was not a great success. We had a good crop of potatoes and onions but, once again, carrots refused to grow and I still have no idea why. I carefully grow them up to seedling size, wait for warm weather and lovingly plant them in a well prepared bed. They then sit sullenly throughout the summer, refusing to get any bigger. Apparently, over 2 billion carrots are planted in the U.K. every year and every year my fifty or so fail to produce any crop. Clearly the gods of vegetables are angry with me and I shall probably have to sacrifice a television garden designer to appease them.

But it is not just carrots, look at these parsnips. The considered opinion is that the manure I added to the soil last year was too fresh, so this year I have had the manure in a heap since spring and spread it over the soil as soon as the crops were lifted, where it will sit all winter being broken down by weather and worms. A light digging in spring should complete the preparation.

I use a lot of horse manure and this is the first time I have had any problems. There is an elderly gipsy lady who comes up from the New Forest twice a year with a van load. We spend an enjoyable 10 minutes haggling a price and then I give her a hand to offload bags of manure whilst her good for nothing son poses with his shirt open to the waste. There have been problems with manure being contaminated with agricultural chemicals, but the New Forest is well away from any intensive farming and our plants, carrots and these parsnips aside, thrive on it, so I think the "too fresh" theory sounds right. We shall see.

Last year we produced a small but excellent crops of cherries and strawberries only for the birds to gobble the lot, so I decided that a fruit cage was needed, plus some extra bird feeders. The birds can live on store bought fruit and we can savour the home grown harvest.

Here it is, partly completed and planted out with some of its eventual bounty. It is a thin steel frame, you can see the door frame at right, over which netting is stretched. You may have noticed that there is no netting on the cage yet, a job I am leaving until next spring.

I have read that cherry trees do not take to being moved, but so far, four weeks after the operation, they show no sign of problems. They could not stay where they were, so if they do fail we will just have to replace them.

The bare root blueberry bushes patiently waiting to enter the fruit cage are looking remarkably spruce for this time of year and there is just a small possibility that they will fruit next year.

Behind them you can just see a pot with a small tomato plant which lived throughout the season in our original greenhouse and gave us a good crop of "Sungold" sweet cherry toms. I dragged it out of the way when I replaced the greenhouse, leaving a few green fruits on and picked the last fully ripened fruit off it in the third week of November. Global warming or what.

All my cabbages, broccoli and Brussels sprouts bolted in the spring. There was a warm dry spell - honestly there was - and I was too busy being a brickie to keep them properly watered. We had a few broccoli leaves, but all the cabbage and broccoli were eventually pulled as there was no point in wasting nutrients on them. However, I left the Brussels and they have come good without any help from me. We will have a good crop just in time for Christmas.

Not a great year for produce, but I have learned a bit more. Next year I will have a couple of raised beds in the new greenhouse to work, plus new trees and bushes and my first attempt at growing peas and beans.

More to learn, a few more failures and, hopefully, a bit more groping toward understanding. It takes ten years apparently to master a craft, any craft, so in another seven I should be able to grow a carrot. Until then, spending a few hours out in the open, turning up enough grubs to keep the incredibly noisy robins fed, will be enough for me.

A window on the world

The other week we had an argument about windows. Our house was built in the nineteen thirties and, apart from the extension at the back, has single glazed painted softwood windows. I was musing that if we were going to sell the house, it might be worth fitting UVPC double glazed windows to the front bays as that seemed to be a selling point for the "House Doctor" crowd. Cami went ballistic; the fitting of plastic windows to the front of her beautiful old house would bring eternal shame on our family and force us to spend the rest of our lives in a lonely desert. It was bad enough having them hidden at the rear.

I pointed out that we wouldn't be living in it and whoever moved in would probably fit them anyway. I just thought that, given my building supply contacts, I could maximise our return by fitting them myself. NO, NEIN, NON, H?T, NEE, JO, NEJ, HAPANA: Apparently I would have to move her dead body out of the way to fit them.

I know when I am beaten, so I started to look at wooden double glazed windows, which are hugely expensive and are difficult to source in an unfinished state. However, this sad tale does have a happy ending. After considerable research, I worked out a way to use the existing frames and replace the sashes with custom made sealed units. Sashes by the way are the opening parts of a window, regardless of whether they are fitted into sash windows or casement windows.

Armed with plans for suitably modified sashes, I got authority from the galactic guardian of windows to purchase a higher spec table saw, a spindle-moulder and planer/thicknesser. With these additions to my toolbag, I could experiment with making my own double glazed windows.

O.K. so what's a spindle moulder?

My next door neighbor gave me a hand to move the machinery from the front drive to my workshop at the back of the house. He is an intelligent young man, so when he asked what a spindle moulder was I immediately said, "It's like a big router."

"What's a router?"

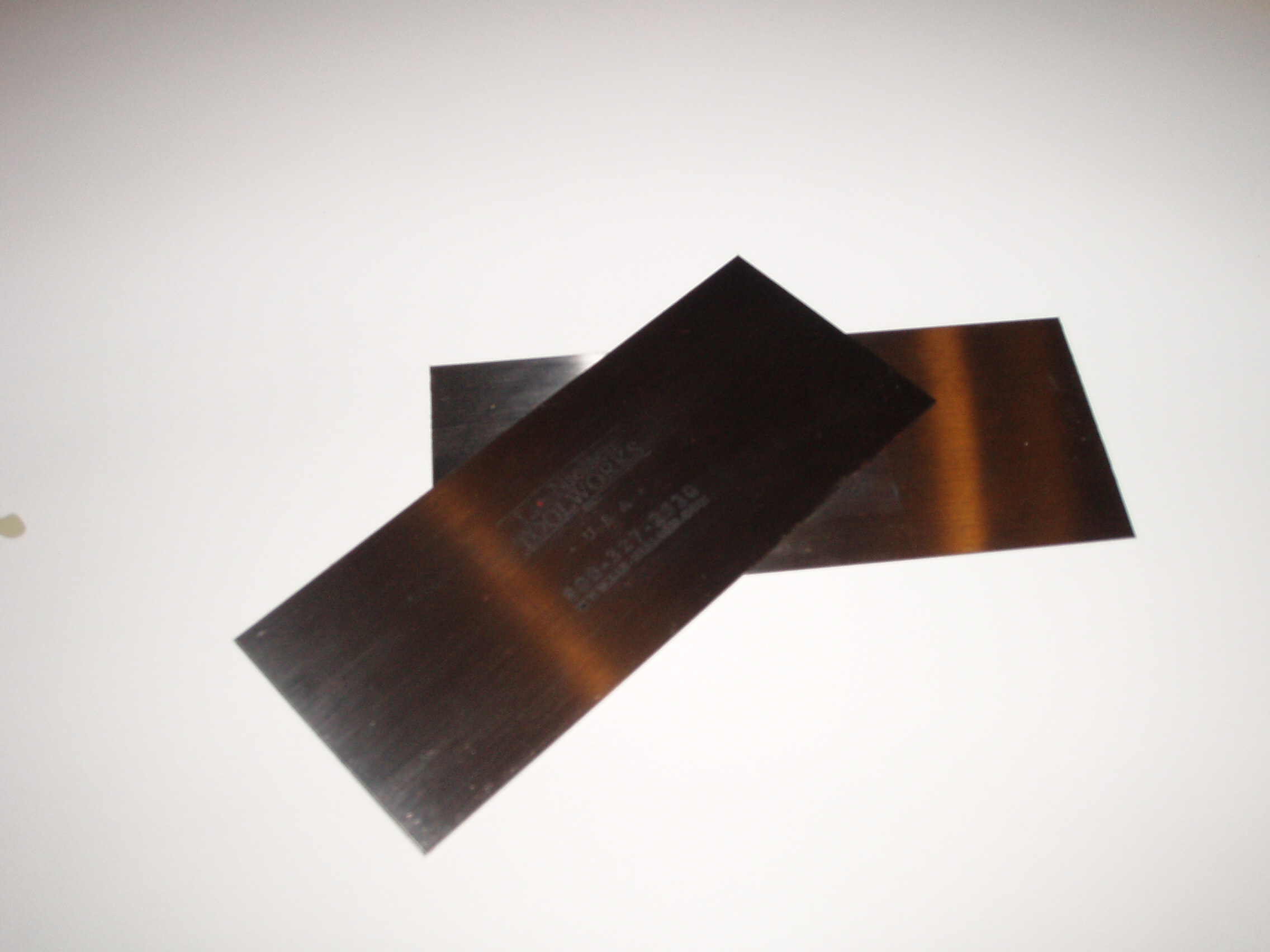

Oh dear. So, for all of you in the iPod generation this is a spindle moulder.

It is, unsurprisingly, a spindle driven by a motor under the table to which various cutters can be fitted, the one shown being a simple grooving blade. I suppose at this point I should warn you not to run it with the guards removed like this, but who am I to lecture when I have been running a table saw without a guard for years, so that I can see what I am doing. Anyway, you may like the red splattered decorative effect.

Raise or lower the spindle to the correct height, pass a piece of wood by it and you end up with a nice groove like this.

In due course two plywood cases arrived on a large pallet and with the help of a half ton mobile engine crane the shiny new machines were installed in my garden workshop. Now, in order to transport such machines, a lot of the sticky out bits and pieces are removed, so the first job was to consult the assembly manual to see how all the rather heavy bits fitted together.

Like all manufactured goods, these American designed machines were built in China. They are imported into Europe by a French company, so the manuals have been translated from Chinese to English via French. As always when reading such documents it is fascinating to see the various language constructs that arise from translation. They range from the mildly amusing - the dust extraction system is called the exhaustion system - to the downright dangerous. The infeed table of the planer is clearly referred to as outfeed and the outfeed table is equally clearly shown as infeed. This could be lethal for someone who doesn't know how such machines react to bits of wood coming at them from the wrong direction, so I have written to the U.K. suppliers to offer my services as a technical author. Anyway, the machines are in place and tested, so I can start experimenting.

Sealed glass units fitted into existing sashes have a bad reputation for failing after about six years, always from ingress of water into the space between the frame of the sash and the gas filled glass unit, causing failure of the glass unit seal and condensation on the inside of the no longer sealed unit. I have therefore designed the sashes so that the glazing bead is on the inside, making the outside watertight. Simple when you think about it and, as there is no putty holding the glass in, it does not matter that the glass is fitted from the inside. Just like high quality European units.

I am looking forward to going into production sometime next spring, with fitting scheduled for the early part of the globally warmed summer that I am expecting. I need to produce twenty four large sashes and twenty four small, so everything will need to be fairly well organized.

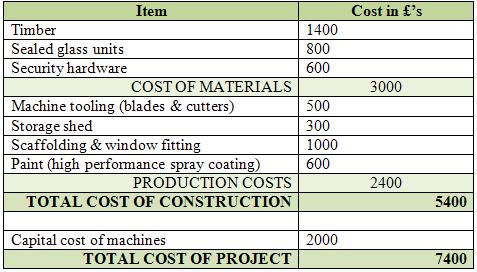

The economics are startling. Buying ready built windows would cost around £20,000. If I build them in hardwood, the figures look like this:

Even including the capital cost of the machines, this gives an overall saving of around £12,400: 63%. It feels as though there is a commercial opportunity here somewhere.

With all this talk of machinery and small scale production, have I lost touch with the ancient craft of woodworking? Have I sold my heartwood to mammon? Not a bit of it. There is still nothing to match bringing wood to a mirror surface with a well sharpened hand plane, but planing some 80 board metres of stock sawn oak down to the dimensions I need would take some weeks on its own. I can complete the job on a thicknesser in a couple of hours and then just skim the surface by hand plane for a perfect finish.

To prove the point about my continued commitment to traditional hand tools, here are the latest additions to my collection, a couple of cabinet scrapers.

A scraper is the simplest tool imaginable, just a piece of steel that is dragged across a surface to flatten and finish it, like a very thin plane blade, but without any plane. In fact the hand plane was a development from the scraper.

Of course, a modern scraper is not just any old lump of steel; it is the result of much metallurgical research and is made of the finest Swedish tool steel, but in essence it is just a lump of steel, that only works because of the skill in hand and eye that you apply to it.

The odd thing about a scraper is how you sharpen it. With all other edge tools, one thing you must avoid is a burr, a tiny piece of metal that hangs off the edge you are sharpening; but with a scraper, you deliberately create a burr. My camera isn't good enough to show you the burr for real, but this is what you are trying to achieve. It is the tiny burr that scrapes against the wood and this is pulled towards you with the scraper slightly bent by thumb pressure.

Of course flattening large surfaces with a scraper would be as tedious as building pyramids, so it is used in conjunction with a plane, but for that final finish that will never need to feel the awful scratch of sandpaper, a cabinet scraper is king.

Barbarian invasion spreads

By this time in 2009, I was hoping to be ready to publish the initial results of my study of the barbarian tribe of Alans. Sadly, project scope creep has occurred and it is all the fault of those idiots that pulled down the Berlin wall.

A huge amount of Soviet archaeology has reached the west since the early nineties and many of the findings have now been translated into English. This has radically changed the received wisdom of what was happening in Eurasia during the 200 years BCE, when the Alans started moving out of the Iranian plain and during the first five hundred years of the Common Era, when they appear in European history.

The Alans, just like most of us, are Indo-Europeans, the largest language and cultural group in the world. It now appears as though the nexus of Indo-European language and culture was in the area that is now Ukraine From there the language and culture spread eastwards as far as the Chinese border, southeast to Pakistan, northern India and Iran, south through to Greece and Turkey, southwest through the Balkans and west throughout Europe.

The later migration of that part of the Indo-Iranian branch that called themselves Alans, which was North West from the Iranian plain to the Caucasus and their current homeland of Ossetia, was therefore something of a retracing of steps back the way they had originally come.

So, a lot more reading and cross referencing before I really feel that I have a handle on these elusive barbarians, but in the meantime, I have come across an enjoyable sidetrack.

There is a theory that Alan cavalry were the basis for the legends of King Arthur and the knights of the round table. This is alluded to in the 2004 film King Arthur, where Arthur is a Roman officer in charge of a Sarmatian cavalry unit (the Alans were part of the Sarmatian confederation at this point in history) defending Hadrian's wall. This was first fully developed in the book "From Scythia to Camelot" by C Scott Littleton & Linda A Malcor. Scott Littleton & Malcor place the origin of the legends firmly in Brittany, where we know a group of Alans settled and which is intimately connected with both some of the early Arthur stories and the development of courtly knighthood. We also know that an Alan sign of leadership was a sword drawn from the earth, a bit like Excalibur. Add the Alans renown as horsemen and their use of fishtail armour and dragon emblems on flags and you get the makings of a nice little da Vinci code tale.

Is there any truth to it? Probably not as a whole. I am sceptical as I think that the derivation of legends is from much wider cultural sources, but some elements, Excalibur perhaps, may derive from a particular source. I am following some of the Breton evidence and will let you know what I find.

Extension of the extension

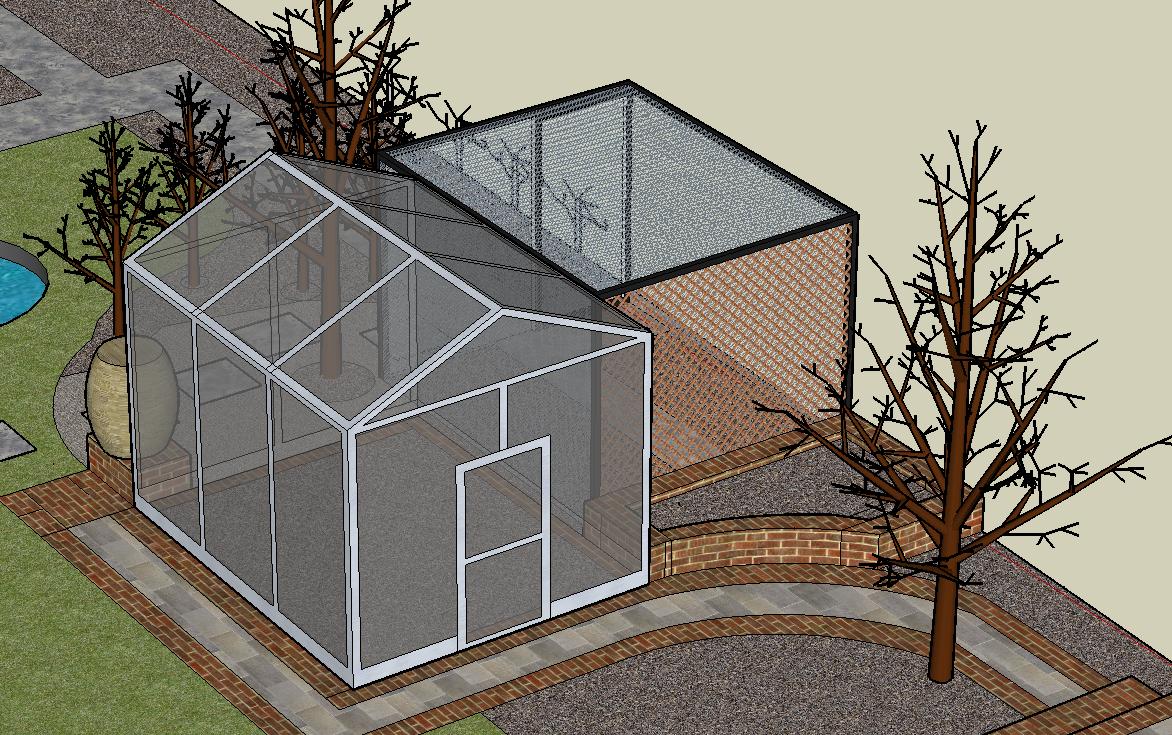

This summer, I picked up from where the builders left off and started extending the hard landscaping of the garden from the end of the new patio. I had been offered a fairly large greenhouse if I moved it from the garden next door, so it made sense that the next area of garden to be developed should include the greenhouse. I am a great believer in General Eisenhower's statement that "a plan is useless, but planning is essential", so a few hours with a tape measure and Sketchup produced this, which concentrates on a particular area of garden rather than trying to plan the whole kit and caboodle.

The trees already exist and the one on the right is our main cooking apple tree, so everything had to fit around the trees and there wasn't that much room between the trees for a greenhouse. I had also already decided that we needed a fruit cage (see "Garden of Delights" section) and therefore pushed the greenhouse away from the boundary to make room for the fruit cage, which dictated a curved path. The raised bed that follows the curve of the path is placed to give some protection to the greenhouse from wheelbarrow knocks et. al.

So, to my first solo building project. I had to build the steps that finished off the patio, a curved path to the greenhouse, a raised flower bed with one curved wall and foundations for the greenhouse and fruit cage. The magic of MS Excel gave me the materials list, a quick trip to the local reclamation yard got us two pallets of local bricks and I ordered up aggregate, sand cement and boarding for concrete shuttering off a friendly building supplies web site.

The procurement of building materials has changed radically over the last thirty years. Once upon a time you had to appear at some grubby trade counter and know exactly what you wanted, as nobody would offer any help. Now you can get small quantities from a DIY outlet or garden centre and the building supply merchants have realised that there is money to be made from the self build market, so they have smartened up their act. We have not quite reached the complete web purchase experience in building supplies as we have in other merchandise, you still have to phone up for some items after finding the specs on a web site, but it is getting there.

One great advantage to DIY building is the contribution it makes to your fitness. Moving 1000 bricks, two tonnes of sand and aggregate and forty bags of cement the thirty metres or so from the front of the house to a storage area at the back was alone responsible for the loss of a couple of kilos of fat.

After carefully watching our extension building crew for five months, I knew that the secret of success is careful laying out and good quality foundations, but there is nothing difficult is achieving either. Firstly buy the longest spirit level you can find and then shell out for good quality, straight timber for the foundation shuttering.

On the left is the foundation for the lower part of the stepped edge and on the right, the completed step. The curve was accurately set in the foundation, so that it was a simple matter, even for a rank amateur like me, to follow the curve with the bricks. The trick to getting a perfect curve in the shuttering is to take a length of 6mm plywood and score one side of it every inch or so on the table saw. This will allow it to bend easily, but retain enough strength to hold its shape when the concrete is poured.

Once the step was in place, the level of the path could be established and voila, a nice walk around an old apple tree to reach the greenhouse.

The pair of willow arches for roses and wisteria to grow through are leaning drunkenly in this picture, due to very high winds the night before the shot was taken. They are clearly going to need more support until the plants colonise them.

All in all, I am reasonably happy with the result so far, but the real test will come next spring when the area is planted up and we can see it fully clothed.

In the meantime, the rest of the winter will be spent putting the glass back in the greenhouse, laying the path along its edge and finishing off the edging on the fruit cage. Then it is back to pencil, paper and Sketchup to tackle the next section, which is the area behind the greenhouse and fruit cage. By the end of next summer, all of the hard landscaping will be finished, at which point we will have to sell the house so that I can start again from scratch.

Seasonal greetings

Christmas is coming and it is the one time of year when I consider becoming religious. I ponder Islamic minarets, Shinto shrines, the Hindu patron of arts and sciences Ganesha and the Noble Eightfold Path of Buddism. Anything to avoid the tawdry Christian festival dedicated to that great deity Toys r Us.

The problem is that I live with someone who, whilst no more religious than me, is enthralled by anything sparkly and shiny. So we have dragged home a tree and I have manhandled the seven crates of Christmas decorations down from the loft. Solar powered strings of fairy lights for draping over trees and bushes are charging up in the front garden and the next week will be spent bedecking the ground floor with swags of woodland leaves, coloured balls and flashing lights. The flashing lights will cause regular blackouts as the local electricity supply fails to cope and generate an energy bill that would look about right for Buckingham palace, but they will sparkle and shine.

On top of that, I will have to pound the exercise bike night and day to slough off the effects of the mouth watering spicy sausage rolls and mince pies with orange flavoured pastry that Cami prepares so beautifully and not forgetting the 80 proof Christmas pudding that is made months in advance.

Despite my scrooge like protestations, there is something satisfying in marking the passing of the shortest day of winter and the first contemplation of a distant but now just visible spring. Bah humbug.

Last updated 07 December 2009