Metallurgy and Mechanics

The Iron age is reckoned to have started between 1,300 BCE and 1,200 BCE, after the copper and bronze ages. It is still going strong, although we convert most of our iron ore today into steel, which is chemically altered iron. Iron is the fourth most abundant element in the earths crust at 5.6%, after Oxygen at 46%, Silicon at 28%, and Aluminium at 8.3%.

Iron ores are minerals from which we can extract iron. Iron is usually found in the following minerals

| Mineral | Formula | Iron percentage |

|---|---|---|

| Magnetite | Fe33O4 | 72.4% |

| Hematite | Fe3O4 | 69.9% |

| Geothite | FeO(OH) | 72.9% |

| Limonite | FeO(OH).n(H2O) | 55% |

| Siderite | FeCO3 | 48.2% |

Iron is extracted from ore by smelting. A process of heating iron ore and some fuel, along with a bit of limestone as flux. The earliest form of smelting was bloomery smelting. This did not heat the ore enough to liquify iron, instead, the iron nodules stuck together to form a bloom. The bloom was then heated in a forge and a blacksmith would hammer away at it to form iron bars, small sheets, and various iron tools. A bloomery is a start and stop process, once the bloom was created the fire would be let to die out. The next stage of iron smelting was to build a brick furnace, fill it with a mixture of iron ore and charcoal, topped off with some limestone and, after setting it alight, keep the temperature as high as possible by using bellows to blow air into the furnace. The bellows would usually be pumped by a waterwheel. The idea was to keep the furnace going by feeding it more ore and fuel until it needed repair.

The Forest of Dean is a site of early iron making. It lies in the western part of the county of Gloucestershire and is bounded by the River Wye to the west and northwest, Herefordshire to the north, the River Severn to the south, and the City of Gloucester to the east.

Iron making was probably first undertaken in the forest during the Roman occupation. It was an ideal spot as iron ore and trees to make charcoal were in abundance. The problem was that trees grow slowly, and iron smelting furnaces burn trees quickly. There was coal available near the forest, but no one could figure out how to prevent the sulphurous elements in the coal from degrading the iron.

Iron making was probably first undertaken in the forest during the Roman occupation. It was an ideal spot as iron ore and trees to make charcoal were in abundance. The problem was that trees grow slowly, and iron smelting furnaces burn trees quickly. There was coal available near the forest, but no one could figure out how to prevent the sulphurous elements in the coal from degrading the iron.

Whilst British trees were a limited resource, there was coal in abundance over some parts of Britain. In 1709 coal, in the form of coke, was first used in Abraham Derby’s Coalbrookdale furnace, in Shropshire and, from then on, either coal or coked coal was the usual fuel for iron making.

The product of the smelter is called pig iron, supposedly because the sand moulds it was poured into resemble a litter of piglets feeding. Pig iron is an intermediate product; there is nothing you can usefully do with it. It needs further processing to turn it into cast iron, wrought iron, or steel.

The product of the smelter is called pig iron, supposedly because the sand moulds it was poured into resemble a litter of piglets feeding. Pig iron is an intermediate product; there is nothing you can usefully do with it. It needs further processing to turn it into cast iron, wrought iron, or steel.

To make cast iron, pig iron, scrap iron, charcoal or coke, and a bit of limestone are heated in a furnace. The limestone acts as a flux, consolidating the unprocessed rock from the ore into slag. Hot air, taken from the top of the furnace is blown into the bottom under pressure, using a bellows. The bellows would have first been powered by human muscle, later by animal power and water wheel, finally by electricity. Molten cast iron is easy to pour into moulds to produce simple shapes such as pot shapes and cylinders, but is brittle, so your pots and cylinders need to be thick and thus heavy.

To make wrought iron, heat the cast iron in a smith’s forge and hammer away at it to produce wrought iron. Wrought iron has less than 0.05% carbon content and is not very strong but is very malleable. It can be made into complex shapes, such as this balcony on a building in Paris, France.

Steel is an alloy of iron and carbon, which has better mechanical properties than iron. Other elements are usually added to the mix to improve certain qualities of the steel. Stainless steel, for instance contains around 18% chromium for oxidation resistance.

The steel industry is a huge undertaking, contributing to about 7% of global greenhouse gas emissions. Emissions from steel production would be much higher, except for the fact that steel is also the most recycled material, with a recycle rate of over 60%. Advanced High Stregth Steel is the latest improvement to available steels. This enables vehicle bodies to be made light, whilst still retaining the strength of older steel bodies.

Steel looks like it will remain our favourite material for making things, from building reinforcement to manometer accurate parts for medical insertions.

Mechanics

A machine is a construction where, if you apply power, will output some work. Machines can be powered by various sorts of energy, human, animal, wind, water, steam, oil products, and electricity. All machines, however complex are constructed from a combination of six simple machines: Lever, Wheel & Axle, Pulley, Inclined plane, wedge, and screw.

Levers

Levers consist of a shaft, which pivots on a fulcrum.They are separated into classes, depending on where the fulcrum is placed. First class levers have the lever in the centre with the load on one side and the effort on the other.  First class levers have the lever in the centre with the load on one side and the effort on the other. Scissors are an example of a first class lever, where the fulcrum is the scissor hinge and the load is the force necessary to cut the material.

First class levers have the lever in the centre with the load on one side and the effort on the other. Scissors are an example of a first class lever, where the fulcrum is the scissor hinge and the load is the force necessary to cut the material.

Second class levers have the fulcrum at one end, the load in the middle, and the effort at the other end. An example of a  second class lever would be a wheelbarrow, where the wheel is the fulcrum and the bucket is the load.

second class lever would be a wheelbarrow, where the wheel is the fulcrum and the bucket is the load.

Third class levers have the fulcrum at one end, the effort in the middle and the load at the other

end. A shovel is an example, where one of your hands is the fulcrum and the other supplies the effort.

Third class levers have the fulcrum at one end, the effort in the middle and the load at the other

end. A shovel is an example, where one of your hands is the fulcrum and the other supplies the effort.

Wheel & Axle

Wheel and axle joints probably evolved from using logs to move heavy stones. Lever up one end of the stone, place a log under it and push or pull the stone over the log, placing more logs in front of it as it moves. Examples of wheel and axle joints,

Wheel and axle joints probably evolved from using logs to move heavy stones. Lever up one end of the stone, place a log under it and push or pull the stone over the log, placing more logs in front of it as it moves. Examples of wheel and axle joints,  apart from the obvious, are a windlass to draw a bucket from a well, a windmill, and a door handle, where the axle is the shaft through the door and the wheel is the motion of the handle.

apart from the obvious, are a windlass to draw a bucket from a well, a windmill, and a door handle, where the axle is the shaft through the door and the wheel is the motion of the handle.

Pulley

A pulley is one or a series of wheels with ropes, belts or chains running over them in grooves. It comes in three types, fixed, moveable and compound. A fixed pulley is stationary, with the wheel usually solidly attached to a beam and the effort required is directly proportionate to the load.

A fixed pulley is stationary, with the wheel usually solidly attached to a beam and the effort required is directly proportionate to the load.  A moveable pulley has one end of the rope or chain firmly attached, with the pulley wheel free to move along it.

A moveable pulley has one end of the rope or chain firmly attached, with the pulley wheel free to move along it.  A compound pulley is a set of two or more pulley wheels, one of which will be fixed. With a compound pulley, it is possible to increase the input effort mechanically, using different sized pulley wheels.

A compound pulley is a set of two or more pulley wheels, one of which will be fixed. With a compound pulley, it is possible to increase the input effort mechanically, using different sized pulley wheels.

Inclined plane

An inclined plane is simply a slope, the principle being that the resistance to movement because of the weight of the load is less than the weight. The load can either be pushed or pulled or, indeed, pushed and pulled. It is thought that pyramid builders made much use of inclined planes

An inclined plane is simply a slope, the principle being that the resistance to movement because of the weight of the load is less than the weight. The load can either be pushed or pulled or, indeed, pushed and pulled. It is thought that pyramid builders made much use of inclined planes

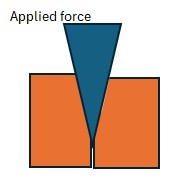

Wedge

A wedge is simply a piece of hard material, shaped to a pointed edge, which is forced into the face of another piece of material, causing it to split on the axis of the wedge. Very large stones can be split into cube shapes given patience and several wedges strategically placed.

Screw

A screw is a shaft with grooves cut at an angle, such the turning the shaft causes it to move along its axis. Examples of screw machines are car jacks, bottle caps and lightbulbs.

A screw is a shaft with grooves cut at an angle, such the turning the shaft causes it to move along its axis. Examples of screw machines are car jacks, bottle caps and lightbulbs.

Joints

When simple machines are combined into more complex machines, they use a combination of four simple joints: Hinged, Sliding, Cam, and Gear. Hinged joints are most often seen in door furniture, but here is a hinged joint in a pair of dividers.

When simple machines are combined into more complex machines, they use a combination of four simple joints: Hinged, Sliding, Cam, and Gear. Hinged joints are most often seen in door furniture, but here is a hinged joint in a pair of dividers.

Wheel and axle joints are self-explanatory.  Cam joints, shown on the right, are where an eccentric component,

Cam joints, shown on the right, are where an eccentric component,  turned by a shaft causes linear movement in a component, called a follower, which is pressed against it. Gear joints, shown on the left, are where toothed wheels engage, and the powered wheel turns the engaged wheel. Most often seen in petrol and diesel engines.

turned by a shaft causes linear movement in a component, called a follower, which is pressed against it. Gear joints, shown on the left, are where toothed wheels engage, and the powered wheel turns the engaged wheel. Most often seen in petrol and diesel engines.

Machine Power

The power output of a machine is measured in the S.I. unit Watt but was first measured by the somewhat arbitrary unit of horsepower, of which there are many different standards. Imperial horsepower is roughly 746 watts, and metric horsepower is around 735.5 watts. One imperial horsepower lifts 550 imperial pounds (250 kilograms) by one imperial foot in one second. There is an electric horsepower, which is exactly 746 watts. Fortunately, the haphazard horsepower measurement has been replaced by watts over much of the world, with the notable exception of the U.S.A.

The power output of a machine is measured in the S.I. unit Watt but was first measured by the somewhat arbitrary unit of horsepower, of which there are many different standards. Imperial horsepower is roughly 746 watts, and metric horsepower is around 735.5 watts. One imperial horsepower lifts 550 imperial pounds (250 kilograms) by one imperial foot in one second. There is an electric horsepower, which is exactly 746 watts. Fortunately, the haphazard horsepower measurement has been replaced by watts over much of the world, with the notable exception of the U.S.A.

Slowly, using just the brainpower of an ever increasing population. We developed more complex and better quality machines. Early machines were powered by human effort, animal effort, water effort, or wind effort. In the middle of the 18th century, steam became important for machine power. It was largely replaced by petroleum product power at the end of the 19th century. The exception being large steam turbines, which are still used for powering ships and in electricity generation. Finally, towards the end of the 20th century, electric motors became powerful enough to drive vehicles, boat, drones, and even aircraft.